El hecho de que muchas industrias y plantas depuradoras se encuentren cercanas a los núcleos urbanos hace necesario la implementación de métodos cada vez más eficaces para la eliminación de olores.

Si bien los métodos convencionales son capaces de eliminar buena parte de las emisiones odoríferas, en algunos casos la eficacia no es suficiente para una población especialmente sensibilizada. Por esta razón es necesario el desarrollo de métodos alternativos que nos permitan explorar nuevas posibilidades de mejora.

Por ello, en Sacyr Agua, hemos desarrollado, a través del Proyecto ODOUR (EEA GRANTS IDI 20140125), cuatro tecnologías eficientes para el tratamiento de olores en procesos industriales y depuración de aguas altamente exigentes por su ubicación y/o características, que están ayudando a solventar problemas de este tipo.

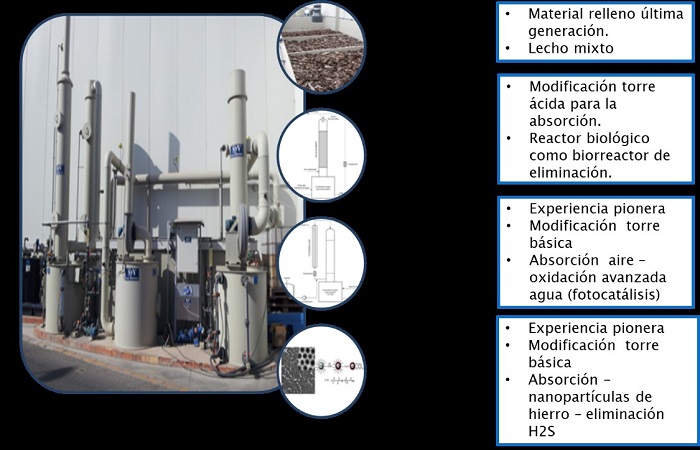

El objetivo ha sido desarrollar técnicas avanzadas de tratamiento de olores, a partir de las convencionales ya existentes, que aporten soluciones más eficientes. Se trata de un sistema de biofiltración avanzada en lecho mixto, un sistema bioscrubber y su combinación con nanopartículas y un sistema de fotorreacción.

Se ha realizado en la depuradora industrial de la Fábrica de Helados Alacant con la colaboración del Instituto del Agua y de las Ciencias Ambientales de la Universidad de Alicante, y se ha desarrollado como continuación de otro proyecto anterior sobre la generación, caracterización, medida y tratamiento de olores en EDARs según fuente de emisión, Proyecto DESODORIZA (CDTI IDI-20090908).

Equipo de Sacyr Agua

Primero, compramos una planta piloto y probamos las tecnologías que más se utilizaban y la tecnología que era más eficiente, además de caracterizar olfatométricamente y estructuralmente los compuestos olorosos del ambiente de la depuradora y diseñar un protocolo de gestión. El complejo de pilotajes de desodorización consta de 4 plantas piloto de 1.000 m3/h de capacidad cada una (incluye: 2 torres de lavado químico – carbón activo – biofiltración – ozono).

Posteriormente con todo este conocimiento realizamos las transformaciones de biofiltración, de bioscrubber, la incorporación de un reactor de fotocatálisis y la configuración con nanopartículas de hierro para acelerar la oxidación de los compuestos de azufre.

Aplicación de nanotecnología

Actualmente las cuatro tecnologías desarrolladas forman parte de nuestro know how corporativo en licitaciones y concursos, además de dar soporte técnico a nuestras explotaciones. Destaca, en este sentido, el sistema de biofiltración avanzada que dio servicio durante más de 3 años, con éxito, como solución definitiva a la línea de pretratamiento de agua de la propia Fábrica de Helados y más recientemente en otras plantas depuradoras, como la de CAPSA (Central Lechera Asturiana), en Zarzalejo donde se ha implementado como mejora al sistema de desodorización existente.

Ahora, la principal dificultad que nos estamos encontrando es la aplicación de la nanotecnología, por su precio, aunque es una solución prometedora debido al gran poder catalítico y de oxidación del sulfuro de hidrógeno que tienen las nanopartículas de hierro”, explica Mercedes A. Calzada Garzón, especialista Técnico I+D+i de Sacyr Agua.

“Además, como resultado de estas investigaciones y la experiencia acumulada a lo largo de estos años Sacyr Agua tiene su propio Protocolo que combina la caracterización sensorial y fisicoquímica simultanea para un mejor contraste de resultados, precisión en la toma de medidas y control del seguimiento”, explica Mercedes Calzada.

Descripción de las tecnologías

- Estudio Diagnóstico: Para la correcta implementación de las distintas soluciones tecnológicas previstas se realizó previamente un mapa de focos de emisiones de las zonas de estudio mediante la novedosa combinación de tres técnicas.

- Biofiltro avanzado: Para aprovechar la capacidad oxidativa de la biomasa y oxidar los compuestos contaminantes en el aire más eficientemente.

- Bioscrubber: Combinación de dos tecnologías: la absorción de los compuestos olorosos en fase acuosa y la oxidación de éstos mediante el uso de microorganismos.

- Nanopartículas de hierro: Se ha demostrado que las nanopartículas de hierro pueden tener también una aplicación en la eliminación de olores dada la gran afinidad que tiene el hierro hacia los compuestos de azufre que son en muchos casos los causantes de los malos olores.

- Fotooxidación: en presencia de catalizadores y luz ultravioleta se pueden formar radicales hidroxilo que son capaces de oxidar la materia orgánica.