Sacyr’s commitment to sustainability, improving energy efficiency, reducing carbon footprint and increasing productivity leads us to create innovative solutions, such as fiber reinforced concrete.

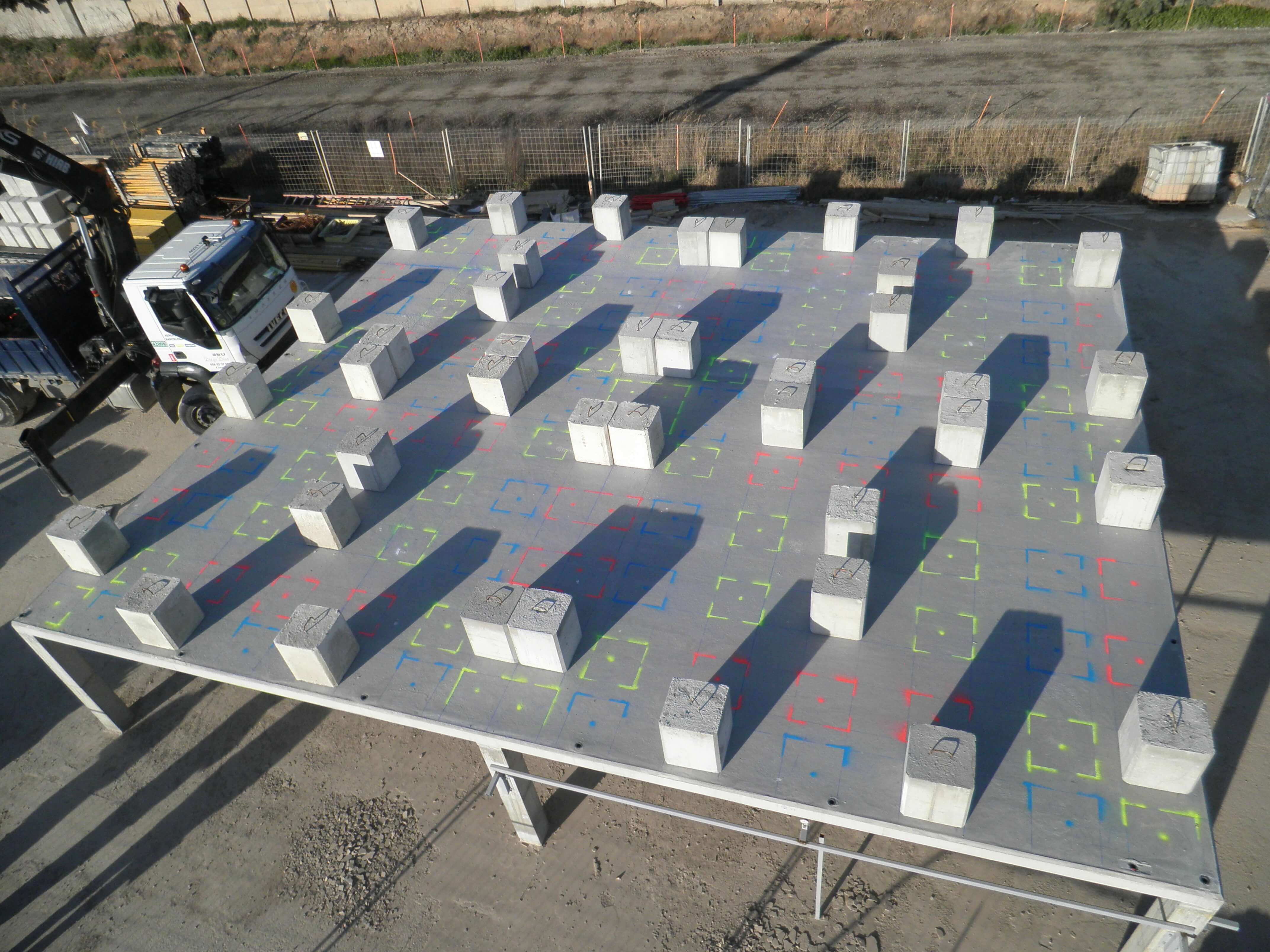

We are working on a project, called eFIB, which has overall objective of developing a new slab system using high-performance steel fiber reinforced concrete (SFRC) without traditional reinforcement.

Use of SFRC has increased significantly in recent years, due to its acceptance in several countries.

It represents one of the most important innovations in the field of special types of concrete. The change in material composition changes its properties: increasing residual tensile strength (under certain loads), durability, resistance to cracking, improving thermal properties, behavior in case of fire, etc.

It handles large loads

“This acceptance and the need for innovation in new construction techniques and materials has motivated research into potential applications of SFRC in structures that bear substantial loads,” explains Ángel Sanchez de Dios, Structural Engineer in the Building Department of Sacyr Engineering and Infrastructure.

In addition, the interest in using SFRC as the traditional reinforced concrete for these types of structural elements relates to advantages such as resource optimization, reduced execution times, reduced environmental impacts and other aspects.

“The concrete is manufactured at the depot and arrives on site where they pour it into the formwork. Labor requirements are reduced in all the processes as steel assembly work on site is minimal, fewer operators are needed for casting on site as self-compacting concrete is used. All these semi-industrialized processes mean an improvement in energy efficiency,” explains Angel Sánchez.

However, consolidating the use of SFRC in slabs requires improved understanding of fiber behavior in aspects related to breakage form and deformation under the action of loads maintained over time. These aspects will improve with long-term use and accompanying regulations to develop these aspects. “With the current cost of fibers, it is also very important to ensure that it can be done with low quantities of fibers to make it cost-effective,” the expert stresses.

Verified viability

“We think that this is a good solution with advantages of all kinds, so we remain vigilant to be able to apply it in some of Sacyr’s new projects, as we have verified the viability of its use in building slabs,” says Angel Sánchez.

With the aim of taking structure to its limit, a load test equivalent to an additional load of 20 people per m2 was carried out, i.e. way above the requirements and above the calculation evaluations. Its behavior against cracking and deflection remained in low, permissible ranges.