Sacyr made significant progress in 2025 towards all objectives outlined in its 2024-2027 Strategic Plan, reinforcing its vision to lead greenfield project development by 2033.

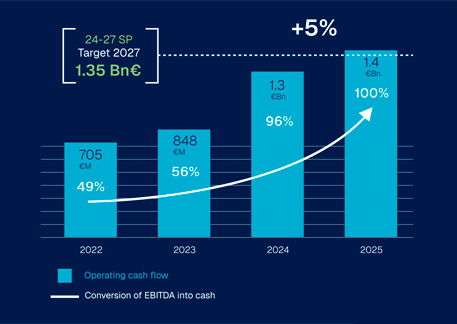

The company achieved an operating cash flow of €1,359 million in 2025, representing a 5% increase from 2024 and exceeded the EBITDA for the period, demonstrating the strength of the company’s concession-based model. Operating cash flow is the most indicative metric of growth and value creation for a concessions company like Sacyr, where 93% of EBITDA is now derived from concession assets. The majority of these assets are either free from demand risk or benefit from risk mitigation mechanisms.

Revenue reached €4,660 million (+2%), while EBITDA stood at €1,358 million, comparable to 2024 (€1,352 million). Net profit, excluding divestments, surged by 46% to €165 million. Attributable net profit for the period was €86 million.

Sacyr successfully reduced its recourse net debt to a historic low of €59 million, down from €344 million in September 2025.

The divestment of three assets in Colombia, combined with increased concession assets distributions, lowered recourse net debt to recourse EBITDA plus concession distributions ratio of 0.18x, significantly below the target set in the 2024-2027 Strategic Plan.

Global credit rating agency DBRS Ratings GmbH (Morningstar DBRS) assigned Sacyr a long-term corporate credit rating of BBB (low) and a short-term rating of R-2 (low), both with a "Stable" outlook. These ratings place Sacyr in the Investment Grade category. This marks the first time Sacyr has obtained a rating from a global rating agency, representing a pivotal step in achieving its Strategic Plan objectives.

Concession Distributions

Throughout 2025, concession assets distributed a total of €224 million, surpassing the 2024 Investor Day target of €191 million (excluding proceeds from divestments in Colombia) by 17%.

The current portfolio of concession assets is projected to generate €19 billion in distributions over their lifespan. This figure has increased by €2.9 billion (+18%) since the 2024 Investor Day, thanks to new project awards and despite the recent sale of assets in Colombia.

Sacyr has already invested or committed €905 million in equity for the 2024-2027 period, nearing its target of €1 billion for this timeframe.

The company retains significant growth capacity through 2033, expecting to have €2.14 billion in available net cash by that date. This figure is derived from subtracting committed equity (€1.6 billion) from expected distributions (€3.74 billion).

Successful Bidding Activity

Sacyr's growth in recent years has been driven by its success in securing new concession awards. While the company averaged three concession wins per year between 2016 and 2023, it secured five new projects in both 2024 and 2025.

In 2025, Sacyr was awarded concessions for: the Novara Health and Science City (Italy); Accesses to Asunción (Paraguay); the reuse water plant in Antofagasta (Chile); the Coquimbo desalination plant (Chile); and the Ruta Pie de Monte (Chile). These five concession contracts represent a combined investment of €1.6 billion.

Sacyr is actively pursuing significant strategic opportunities in its key markets, including the USA, Canada, Italy, Chile, Australia, and the United Kingdom. In the USA, the company is part of shortlisted consortia for "managed lanes" projects on I-285 East in Georgia, I-24 in Tennessee, and I-77 in North Carolina, and is also engaged in three other bidding processes.

Cash Dividend Payment

In July, Sacyr paid the first cash dividend (gross €0.045 per share) under its Strategic Plan, totaling an outlay of €36 million. In line with this Plan, at least €225 million in cash will be allocated for shareholder remuneration between 2025 and 2027.

Additionally, in January 2025, a scrip dividend was issued, offering one new share for every 40 shares held (equivalent to €0.078 per right). 87% of shareholders opted to receive their dividend in Sacyr shares.

Business Area Performance

Concessions.- Sacyr Concesiones reported revenue of €1,892 million (+8%). While operating income saw a 4% decline, construction revenue increased by 50%, driven by progress on the new Velindre Cancer Centre (UK) and the Buga-Buenaventura (Colombia) and Ruta de la Fruta (Chile) highways.

EBITDA for this period stood at €755 million (-14%), primarily due to the accounting impact of financial asset performance and the divestment of Colombian assets.

Concession distributions reached €212 million.

Engineering & Infrastructure.- The strategy for this business line focuses on achieving a stable EBITDA margin of approximately 5% and ensuring that the majority of its backlog serves Sacyr Concesiones. In 2025, this backlog accounted for 73% of the total, aligning with the 2024-2027 Strategic Plan.

Revenue reached €2,971 million (+8%), and EBITDA increased by 31% to €552 million. These increases are mainly attributable to contributions from Italy, the UK, Colombia, and Spain.

The total backlog for Engineering & Infrastructure grew by 18% from year-end 2024, reaching €12,470 million.

The construction activity's EBITDA margin remained stable at 4.8%.

Water.- This business line experienced strong growth in 2025, achieving revenue of €307 million (+25%) and EBITDA of €62 million (+23%). Profitability, measured as EBITDA margin, improved to 21.7% from 20.6% in 2024.

This growth reflects the solid performance of existing assets and new project awards in 2025, solidifying Sacyr's position as Spain's leading company by operational desalination capacity.

Water distributions totaled €12 million.

The backlog grew by 45% to €6,979 million, notably including the award of the water reuse plant in Antofagasta and the Coquimbo desalination plant, both in Chile. Additionally, multiple contracts were secured in Spain, including projects in Málaga, Vitoria, Huelva, Badajoz, and Tenerife, among others.