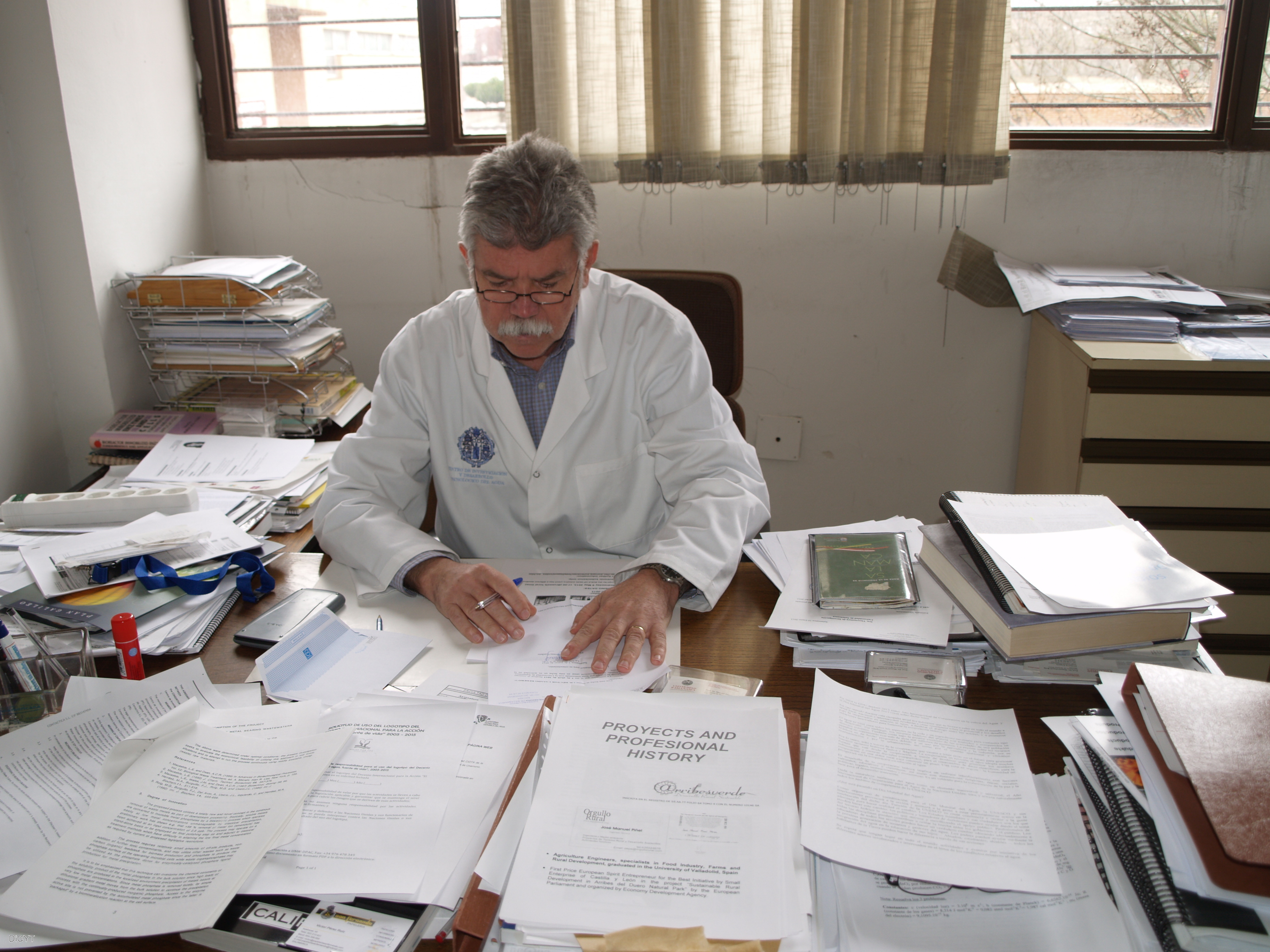

Manuel García Roig, deputy director of the Water Research and Technological Development Center (CIDTA) at the Universidad de Salamanca, explores this line of research in his laboratory.

Some examples of metal-absorbent biowaste dissolved in wastewaters include mammalian hair and bird feathers, residual byproducts from industries like tanning, meat production, poultry farming, etc. In most cases, the biomass, consisting almost entirely of pure keratin, the most abundant protein on the planet, burns or biodegrades (with some difficulty) at landfills, rather than being appropriately applied to technological processes. As necessity is the mother of invention, "For years people in India have been using animal hair—keratin—hydrolyzed through physical-chemical methods to produce nourishing peptide and amino acid mixtures for animal feed,” Roig explains.

Other absorbent industrial biowaste includes:

a) lignocellulose (straw, dried tree bark, nut shells, orange rind, olive pits, etc.) rich in cellulose and lignin biopolymers.

b) arthropod exoskeletons (insects and crustaceans), from the seafood industry and the emerging insect farming industry, which consist of proteins, calcium carbonate, and mainly chitin, the heteropolysaccharide N-acetylpolyglucosamine from which chitosan, another important and widely used biopolymer, can be easily obtained through deacetylation.

c) exhausted saccharomyces cerevisiae yeasts extracted from brewery fermenters, consisting of chitin and α (1.3) β-D-glucans.

All of these biowastes, when suitably pretreated and crushed to clean them and increase their absorbency, can serve as bioreactor fillers to decontaminate metal bearing-wastewaters. Thus, it is possible to give these industrial byproducts added value within the sustainable context of circularity.

Biometal DEMO Project

Roig’s most recent experience involved the European Biometal project, DEMO (Biometal Demonstration plant for the biological rehabilitation of metal bearing-wastewaters), which sought new technologies to treat industrial waters contaminated with metals (zinc, copper, lead, manganese, etc.). From the outset, scientific coordination of the project was handled by CIDTA, since the idea for the project originated in Salamanca, as did the formalization of the consortium of companies and researchers participating in the initiative. The budget totaled EUR 4.3 million, 2.9 million of which was provided by the EU and the remainder from the partners.

“This project, developed between December 2013 and December 2017, concluded with the commissioning of a pilot plant in Portugal’s São Domingos mine (Algarve); another pilot plant at Industrial Goñave (Valladolid), dedicated to metal plating; a third at Endeka Ceramics S.L. in vall D'alba (Castellón); and two more at Hidrolab, S.L. (Albacete). For the last two years, we worked on the project at five plants in total, checking industrial wastewater—with the different biotechnologies that we had studied and developed at laboratory scale during the first two years—against synthetic and real wastewater.”

Researchers focused on the following: a) the bioprecipitation of metals, in the form of sulfides, using sulfide-reducing bacteria (SRB); b) the bioprecipitation of metals, in the form of phosphates, using phytase enzymes and acid phosphatase; c) the bioabsorption of metals with sugar beet pulp and brown algae; and d) the bioabsorption of metals with hydrogels and pearlites based on alginate, chitosan, and polyethylenimine derivatives.

The tested biotechnologies work well when contamination levels are not too high, in the range of 1 to 80/100 ppm (mg/liter) of overall metal concentration, but at higher concentrations of more than 300 – 500 ppm, for example, bioabsorbents quickly become saturated. It is advisable, therefore, to subject the metal-bearing waters to a secondary active physical-chemical treatment, normally chemical precipitation by the addition of bases, to eliminate the metals from the wastewater. Because these treatments require energy and generate substantial quantities of sludge, tertiary treatment is required, and it is here that the more sustainable biotechnological treatments—metal bioprecipitation and bioabsorption—take center stage.

The pilot plant at the Algarve mine, which is managed by the São Domingos municipal treatment plant, continues to operate and treat the mine’s water.

European Green Deal

Based on the development and results of the DEMO Biometal project, Roig’s research group (integrated into a European consortium) will enter the Horizon 2020 European Green Deal call, in the Zero-pollution, toxic-free environment category. If the project is accepted, various biotechnologies will be used, including the biodegradation of emerging organohalogenated contaminants, the co-treatment of heavy metals and emerging pollutants with bioabsorption/absorption, as well as certain physical-chemical methodologies for the chemical (photo, electro) degradation and absorption of the most persistent emerging pollutants. In this new project, the São Domingos pilot plant in the Algarve, among others, will use the same biometal sulfide-reducing bacteria, adapting it to remove metal from acid mine drainage, while simultaneously biodegrading emerging contaminants from polluted waters.