José Luis Abia Pascual / Innovation specialist at Sacyr Engineering and Infrastructure

Last Wednesday August 23, 2023, at around 14:34 CEST, the Chandrayaan-3 lunar exploration mission Vikram lander touched down at its destination, the surface of the lunar south pole region without issues. This mission made India the fourth country successfully landing on the moon and demonstrating their technological abilities to remain a player in the space race.

What does this successful moon landing by India entail? The answer is complex. India is the first country landing on the moon’s south pole, which according to current research is the optimal place for human settlements due to its shared weather conditions with Earth, meaning this mission sets the course for how other countries will land, settle, research and build in the coming years.

In order to build on the moon, we need to use construction materials able to withstand the extreme weather conditions using resources found on the moon. Moon soil is called regolith and is currently undergoing test-outs to make materials such as concrete, metals, ceramics, and composites from it:

Sulphur-based lunar concrete: with water being a strategic resource on the moon, sulphur replaces it as a ligand. This poses a significant advantage, since sulphur is abundant on the moon’s surface and concrete would acquire from 70 to 80% of its maximum resistance within 24 hours. But it also brings on several downsides, as temperature shifts significantly reduce its resistance; the ligand separates from the concrete, losing strength, and it performs poorly in space vacuum.

Polymer lunar concrete: consists on replacing water with thermostable plastics. The experiment was done on JSC-1A, a NASA-proprietary lunar regolith simulator and epoxy resin. After mixing the two, they were compressed to achieve greater resistance. This material is considered a fast way to build structural elements on the moon.

Metals: Aluminum, iron, titanium and magnesium are the elements with the highest concentration in lunar regolith. In case a technology to extract oxygen from chemical compounds in regolith were to be developed, these materials would be byproducts usable in infrastructure construction.

Ceramics: Due to how fine regolith is, its vitrified materials and basaltic composition several research lines have been conducted focusing on its application on ceramic materials, made from direct synthetization using microwave or laser technology to melt basalt or making lunar glass as construction material. Basaltic regolith is estimated to feature compressive strength of strength to compression of 538 MPa and tensile strength of 34,5 MPa, much higher than basaltic compounds found on Earth.

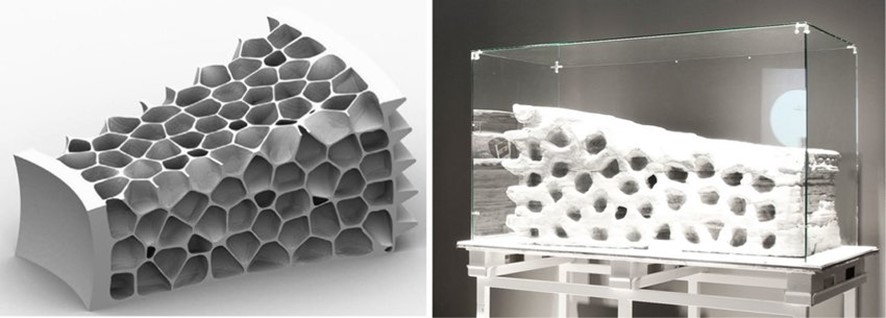

Materials for 3D printing: In 2014, the European Space Agency made a structure with lunar simulant DNA 1 with 3D printing technology. This material was 3D printed in layers that were compressed, achieving compression strength of 20,35 MPa and flexural strength of 7,11 MPa.

Graphene regolith-based magnesium oxychloride composite materials: This composite is made in a fresh place adding lunar regolith, magnesium oxide (MgO), Magnesium Chloride Hexahydrate and graphene nanoplatelets to improve the properties of this material, which is then poured into molds and left to harden. This material performs well under temperature shifts and holds its mechanical properties, making it a good candidate for lunar construction material.

Bringing real regolith to Earth is very expensive, so in order to develop these materials lunar regolith simulant is used instead. Regolith simulants are composite blends using different materials found on Earth to create composites with chemical and mechanical properties very close to that of the regolith samples brought by American, Russian and Chinese space missions.

There are multiple simulants, one of them being LZS-1, which was made from basalts from Lanzarote by the IGEO-CSIC, showing Spain’s commitment to the development of the space sector. The best-known simulant is JSC-1ª, developed by Orbitec in collaboration with NASA.

Considering the number of materials being tested for construction, growing crops, etc. on astronomical objects like the moon or Mars, it seems more cost-efficient to test on the moon rather than Mars considering how long it takes to get there (four days vs. seven months) and with space travel costs at historical lows, how long will it be before the first feasible P3 project on the moon? And, who will deliver it?

India aterriza en la Luna

https://elpais.com/ciencia/2023-08-23/la-mision-chandrayaan-3-de-la-india-aterriza-en-la-luna.html

Crawford IA. 2015. Lunar resources. Progress in Physical Geography: Earth and Environment

http://journals.sagepub.com/doi/10.1177/0309133314567585

LZS-1, Lanzarote (Canary Island, Spain) lunar (Apollo 14) basaltic soil simulant

https://www.nature.com/articles/s41598-022-20960-8